Rhenish Ring Kiln

one of the last of its kind

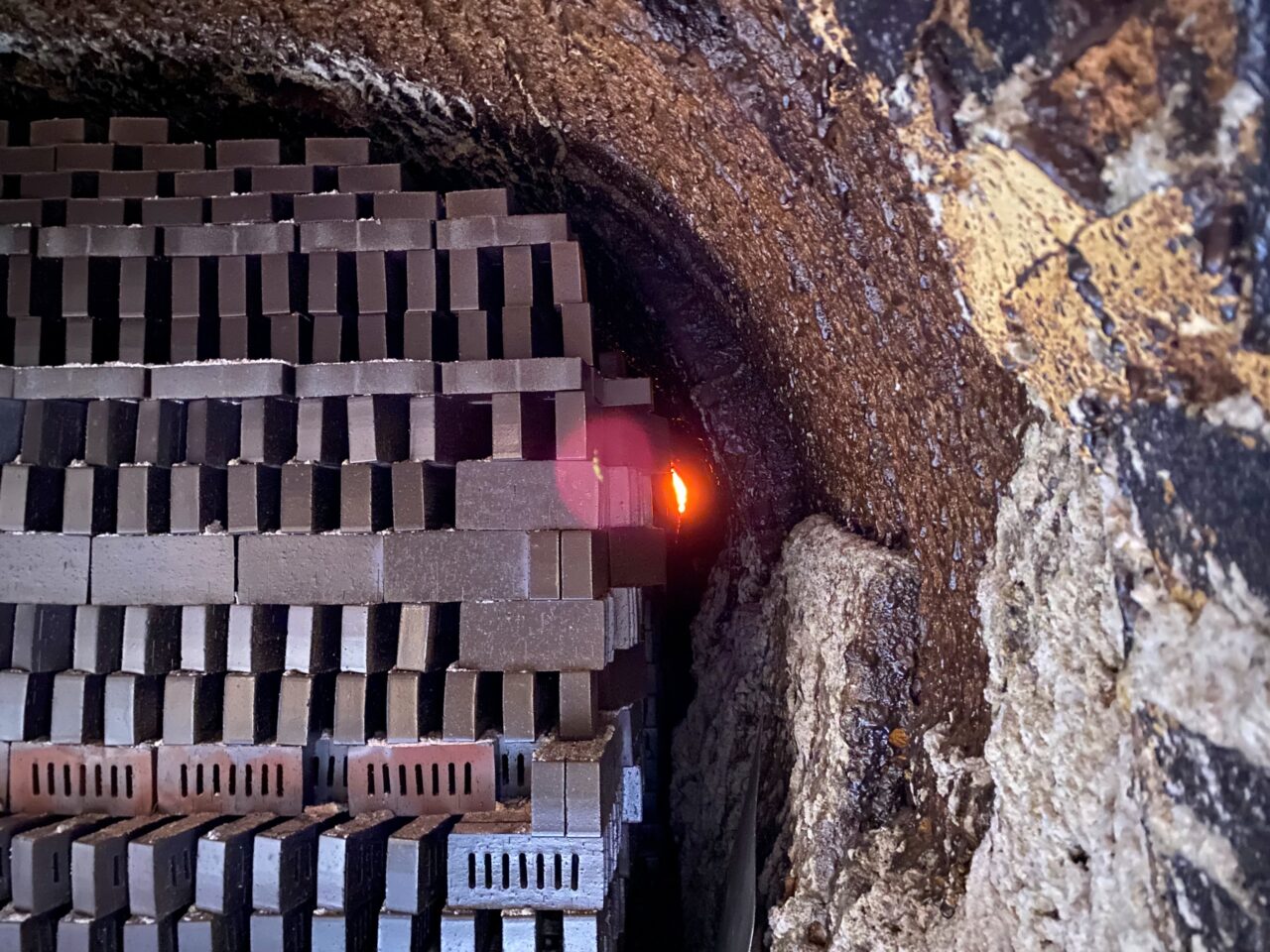

The historic ring kiln

of Gillrath Brickworks is a rarity and at the same time a special feature as the last producing ring kiln in NRW and one of the few remaining in Germany.

We are the only manufacturer in western Germany that still operates a historic ring kiln for firing bricks and clinkers. This is our unique selling point and the reason for the special surfaces, colors, and textures of our products.

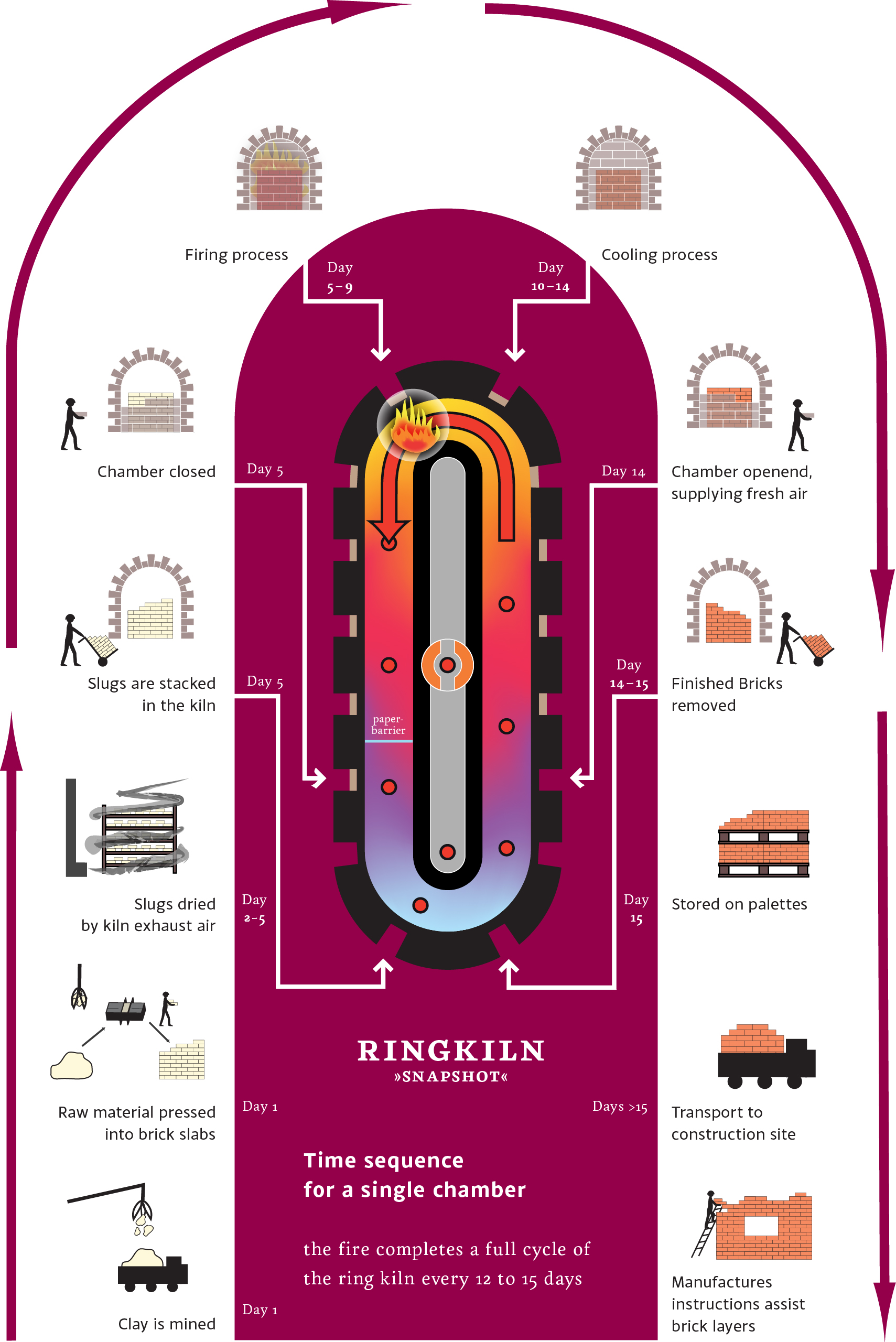

With the invention of the ring kiln by Hoffmann in 1850, it was possible for the first time to fire larger quantities of bricks in a continuous burning operation while saving fuel. The ring kiln reduced the coal addition to 1/3 of the previous ovens and was to remain the standard in the brick industry for more than 100 years.

Unique colors and surfaces can be created by firing in the ring kiln. Such depth of colors and the special haptics of the stones can only be produced in the ring kiln manufactory, although the large industry tries to imitate these effects by artificial pressure. But the original ring kiln firing remains incomparable and beautiful with a special character even after decades.

In the ring kiln, we have hundreds of possibilities to set the stones, as this is still done in laborious manual work. There are also numerous firing recipes for firing in the ring kiln – from the addition of a lot of coal or salt to calm oxidizing firing.

The continuation of the more than 150-year-old craftsmanship fills our company, employees, and family with pride and humility and is at the same time a responsibility to maintain this as an example of living industrial culture for future generations.

The Hoffman ring kiln

is the heart of the clinker works

Our ring kiln convinces here!

The ring kiln is characterized by its great fuel economy. The fired bricks are cooled with fresh air, which is thus preheated for combustion. The combustion gases are used to preheat the freshly inserted blanks. — The ring kiln is one of the most economical firing units ever.

Process Principle

- Continuous firing operation in a closed firing channel.

- Fueling from above through the kiln ceiling.

- The stationary firing with circulating fire characterizes the ring kiln.

Standards

We generally manufacture our clinkers according to the European masonry brick standard DIN EN 771-1. However, deviations in size and shape are desired in our coal fires.

Temperature

Our ring kiln fires at temperatures up to 1,200° C.

Improvements

Through constant improvements to the formulas and firing processes, the ring kiln clinker remains an innovative product.

This ensures the typical properties

Longevity, value stability, very good thermal insulation, and natural fire protection.

… interested in more information about our production?

Seminars & Factory tours

We offer various tours of our factory for interested parties and professionals. In addition to pure factory tours, you can also take a brick baking course or professional seminars with us.