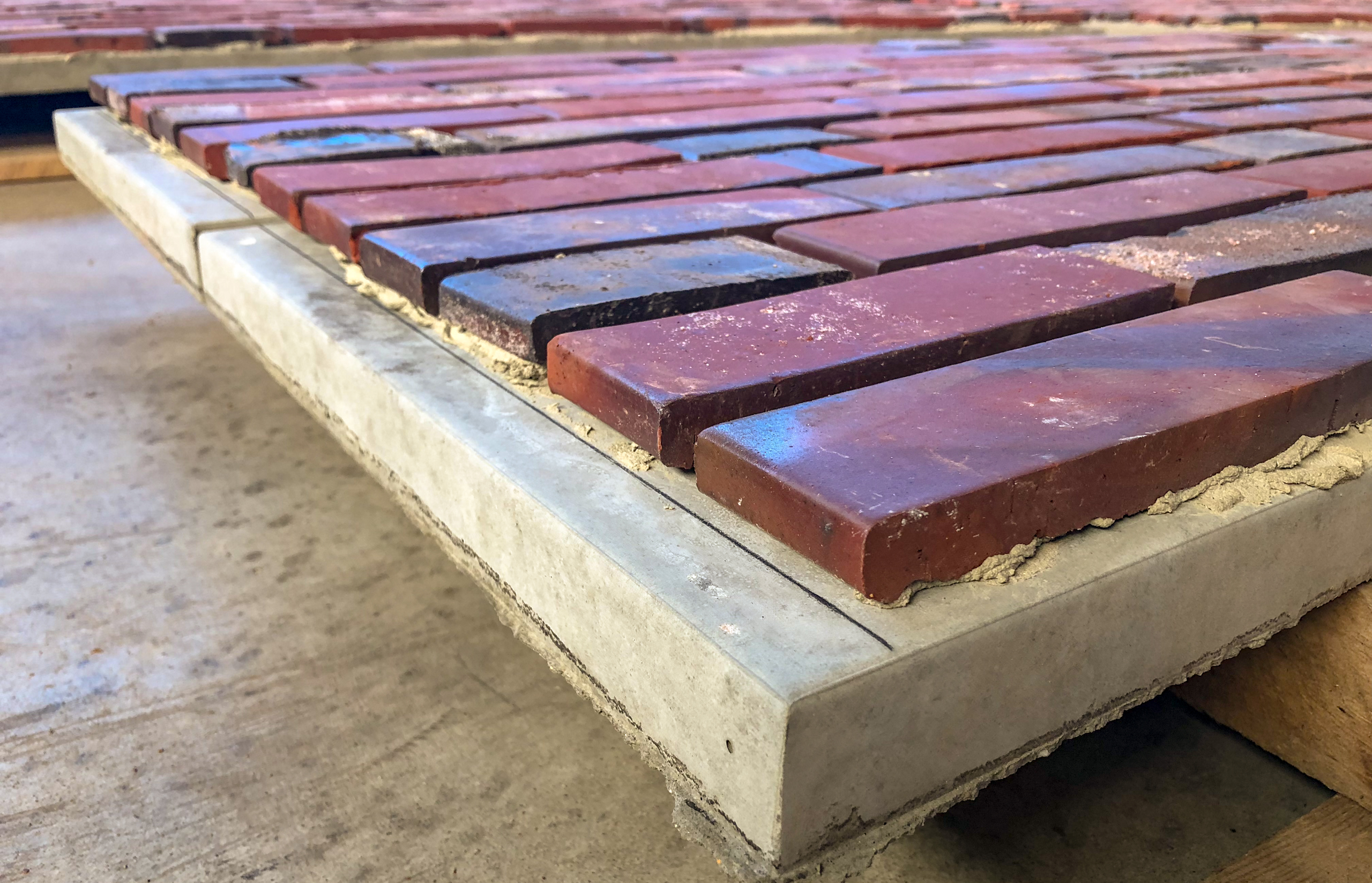

Processing Instructions for clinker brick slips

Make the most of our brick slips

Each slip is unique

… for the special brick facade.

Ring kiln-split slips can have certain dimensional tolerances that must always be taken into account.

In principle, the general processing instructions for our bricks apply to the processing of brick slips.

The right mix is essential

to achieve a harmonious overall appearance

Therefore, care must be taken to create a lively play of colors in which the different surfaces alternate continuously, but no color clusters, e.g., exclusively glossy slips, appear in one place.

Professional processing of brick slips

with External Thermal Insulation Composite System (ETICS)

We are happy to provide you with test certificates for the brick slips, which you can discuss with your ETICS supplier.

When processing brick slips, angle and corner slips are glued to corners and reveals, while standard stretcher slips and, depending on the bond, header slips are glued to the surface. In a further step, the slips are inserted.

Unlike brick stones, slips can only be flush grouted, as a recessed joint is not possible due to the thinness of the slips.

Processing Instructions for Brick Slips

DE only | Status: Oct. 2022