Essential information

for processing

Get more out of our bricks

The individuality and uniqueness of a brick facade can be further enhanced by special masonry bonds and by emphasizing the special characteristics of the clinker.

Once the decision has been made in favour for a clinker facade, the next thing to be clarified is whether you want to use a full clinker or a brick slip. There are big differences in the processing of clinker and clinker brick slips.

On this page and on the topic

Processing of bricks

Steel anchors connect the backing masonry with the facing masonry. The rear masonry is connected to the exposed masonry by steel anchors. With the multi-layer wall structure, the clinker meets a wide range of requirements such as weather, heat, noise and fire protection.

Tips

for processing bricks on the construction site.

- The stones should be mixed across 4 to 6 pallets.

- Start bricklaying at a less important spot. This way, you can develop a feel and eye for the color of the brick to process it better in essential visible areas.

- As the brick has low water absorption, the processing may take longer than with a highly absorbent brick. Process the brick around the house, which distributes the work surface.

- During processing breaks, the freshly created masonry should be covered with counter-battens and foil to prevent water from getting into the backing masonry. This also protects the masonry from other adverse weather conditions.

- When bricklaying, pay attention to possible water sources at the house. These water sources should be diverted away from the masonry to avoid consequential damage. If the masonry or backing masonry has become very wet, it should dry well before pointing.

- Broken stones in the pallets can be used as headers or 3/4 stones.

- We recommend alternating processing (front and back) for most bricks.

- Our bricks can usually be somewhat larger on the back and have certain dimensional tolerances. The layer dimension should therefore not be calculated too small.

- For quantity calculation, a standard breakage of about 5% should be included.

Processing instructions for bricks

DE only | Status: Oct. 2022, 1MB

Characteristics

of our bricks

No two are the same.

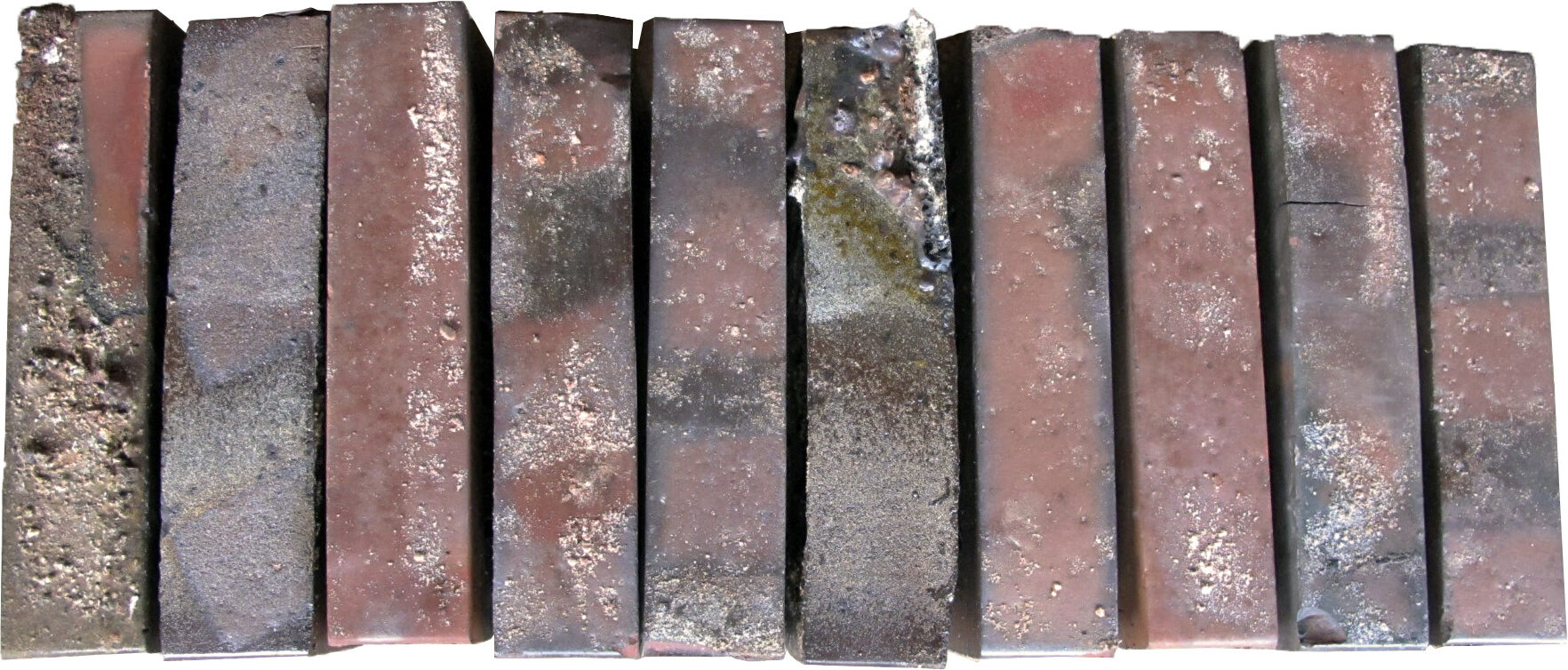

Most of our bricks should be processed alternately (front and back). Small cracks, coal burnouts, and chippings are part of the characteristics of our coal-fired bricks.

The mentioned features are generally part of firing in a circular kiln. These are also not subject to complaints.

If the rustic and unique stones are sorted out in coal-fired bricks, the overall appearance loses liveliness.

Above all, the setting method in the oven gives the bricks a changing color change.

The salt and coal mixture, which we add during coal firing, can burn onto the stone in the circular kiln.

The joint

is the most critical point in the masonry.

For bricks, we always recommend mortar group II or IIa for the masonry mortar. Under no circumstances should trass cement be used.

To achieve a lively interplay of light and shadow in the facade, the mortar should be well scraped out when bricklaying so that the joint can be recessed.

If a dark or colored joint color is chosen, the bagged product of a joint mortar color should be chosen to obtain a beautiful and even appearance.

For pointing the brick slips, there is also a special joint mortar for this requirement.

Effect of joint color

The choice of joint color is a matter of taste.

There are countless joint colors, ranging from light white and beige shades to various gray gradations to dark anthracite and black shades.

In general, the lighter the joint color, the more the joint and its homogeneity are emphasized. In contrast, with dark joints, the stone is accentuated more, and the joint recedes into the background. However, this can also increase the liveliness of the facade. Generally, the choice of joint color is a matter of taste.

Another option for a more uniform facade appearance is choosing the joint color in the color of the brick, e.g., a red joint for a red stone. Here, the contrasts between the joint and brick blend, resulting in a very even overall appearance.

The appearance of the facade is significantly influenced by

the brickwork bond

Stretcher bond

The stretchers are placed so that they are offset by 1/4 or 1/2 each time.

Block bond

Stretcher and header layers alternate.

Cross bond

Similar to the block bond, but with an additional stretcher layer offset by half a brick.

Gothic bond

Stretchers and headers alternate. The rows are laid offset by 1/4 brick each.

Random bond

Irregular bond. Some headers are irregularly interspersed. No more than five stretchers should be laid in a row.

Order adapted to the brickwork bond

Helpful information for processing

We can also offer you appropriately cut header slips for the processing of thin brick slips in a brickwork bond with a high header content.

Expansion joints

To avoid damage to the building envelope

To avoid these damages, it is important to pay attention to expansion joints during the planning of the house. These joints absorb the deformation of the adjacent components without stress and thus help to avoid cracks and deformations.

The expansion joint should be placed as inconspicuously as possible, for example behind downpipes or in building corners. It can also be adapted in color to fit the overall appearance of the building.

The width of the expansion joint should be at least 15 mm.

Design possibilities

For individual facades with exposed brickwork

The construction of exposed brickwork with clinkers requires craftsmanship combined with modern technology. This does not only involve laying brick on brick. Brickwork can also be provided with great design elements, such as:

- Grid and perforated facades ( Lünen, community center – DE content)

- Perforated brickwork ( Anklam)

- Reliefs (Plumstead Libary)

- Ornamentation (Isernhagen)

- Decorative brickwork (country house in Wegberg – DE content)

- Höger layers (with projections and recesses) (Rheinkai 500 – DE content)

- Material mix of clinker with another material such as Trespa, wood, plaster, glass, concrete

- Various color combinations (Hamburger multi-family house – DE content, Anklam, Genthinerstr)

- Use of clinker for elements other than the facade, e.g., indoors, or for garden design

Processing of prefabricated parts & lintels

Every builder who builds with clinker has to deal with the question of how a clinker lintel should be executed.

Nowadays, however, this is the exception, and a builder has the choice between the alternatives of clinker precast lintels or stainless steel angles. This choice is mainly based on aesthetic considerations. The advantage of clinker precast lintels is that they do not stand out visually, and the clinker is very well accentuated.

Various manufacturers can be used for the creation of clinker precast lintels. We would be happy to provide you with contact information for appropriate specialized companies that we can recommend.

In the images, you can see how precast lintels are attached to the facade using brackets.

Facade cleaning

For cleaning freshly built brickwork, it should first be gently brushed off. Then, the brickwork should be wetted from bottom to top.

With lukewarm water and a brush (e.g., a root brush), possibly with the addition of detergents and softeners, start cleaning the brickwork from top to bottom.

Heavy soiling

For a heavily soiled facade, the pre-cleaned and pre-wetted facade surface can be treated with suitable, special cleaning agents. After cleaning, the facade should be immediately rinsed with plenty of clean water. The use of acids should be avoided. Please feel free to ask us for a suitable cleaning agent or tips from professionals.

Caution when using hydrochloric acid

For certain bricks, the use of hydrochloric acid can lead to discoloration or efflorescence. This mainly affects the following clinkers:

- Clinkers with glazed or engobe surfaces

- Steamed clinkers

- Clinkers made of yellow to white firing clay

- Brown manganese-containing clinkers

We strongly advise against cleaning with chemical substances or even hydrochloric acid!

»Gillrath

Bigpacks«

Another building block of the circular economy in the brick factory

Only clean, sorted, and unadulterated brick breakage should be collected in this big pack. Please place the full big pack at the edge of your construction site so that our truck driver can pick it up.

We have the collected brick breakage ground up, creating brick dust.

Today, we already add about 5% brick dust to each production. This brick dust has stored the energy of a fired clinker. By adding it, a portion of sand can be saved.

Circular economy in the brick factory

DE only | Status: Feb. 2022

Our pallets

are deposit pallets!

Please stack the big packs and pallets for collection so that our driver can quickly and safely pick them up. Our truck driver does valuable work, and he will only take the items if they are carefully stacked for collection. Thank you for your support in protecting our environment!